We took a family trip to the Manchester Christmas market. It all started with a fantastic breakfast at Bills. A new Steele family tradition has been born

Kinky Boots

No electricity

A happy work environment

An even better mushroom start to the day

The competition for Santa Maria

Several people opine that Santa Maria is the best pizza place in Ealing if not the whole of London. We recently heard that L’Oro Di Napoli, right around the corner, was even better. We went, ate, drank and had fun. It was a great place and we thoroughly enjoyed it. I still think Santa Maria is a little better but I haven’t been for a while so maybe I should check it out again soon

PSVR

Omelette Pan

Autumnal Fun

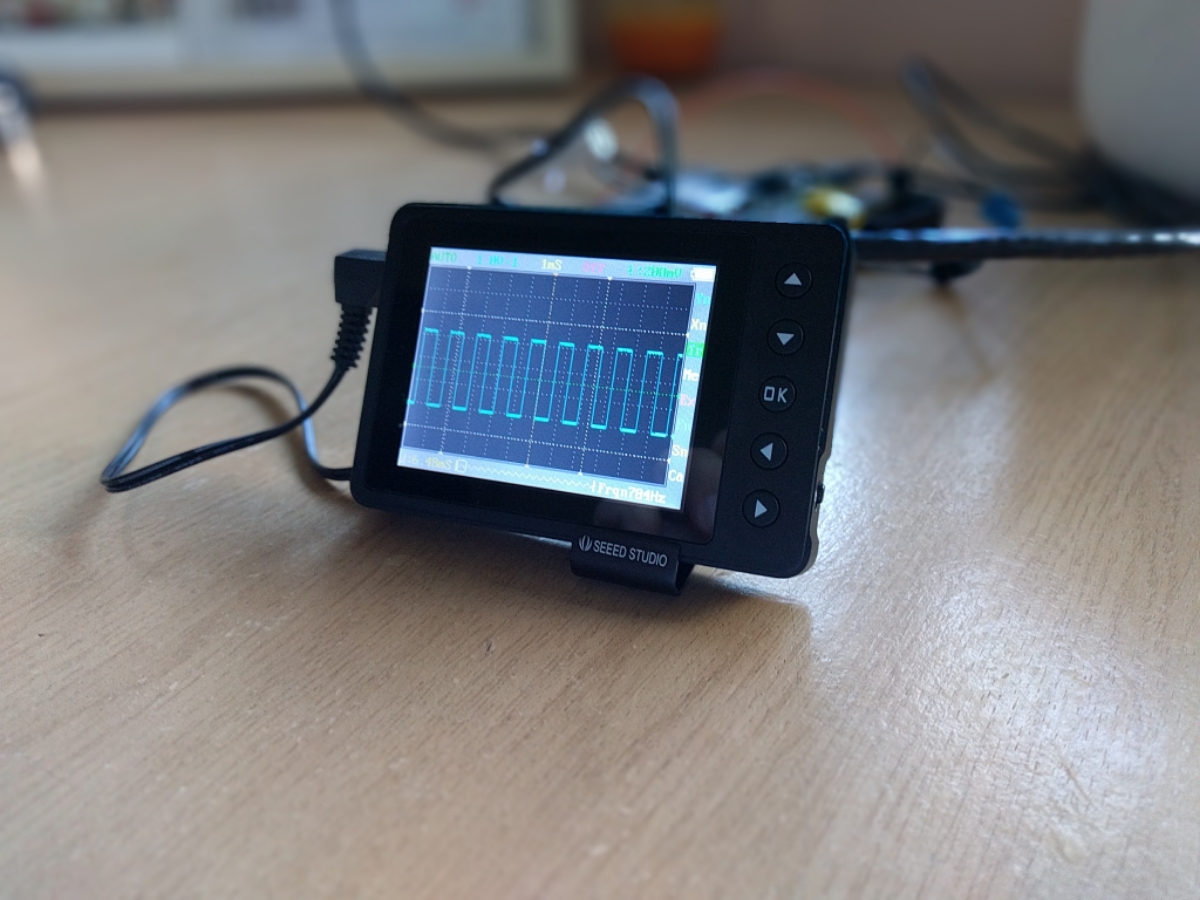

Oscilloscopes

Spent an awful long time trying to work out if my smoothieboard was giving me a decent PWM signal. The only way forward was to grab an oscilloscope.

Once I had an oscilloscope I had to work out how to use it. So I fired up an old raspberry pi. Wrote a bit of python to drive one of the GPIO lines and boom. We’re in business

Afternoon off

See Ya

Street food in China town

Fan Repair Failure

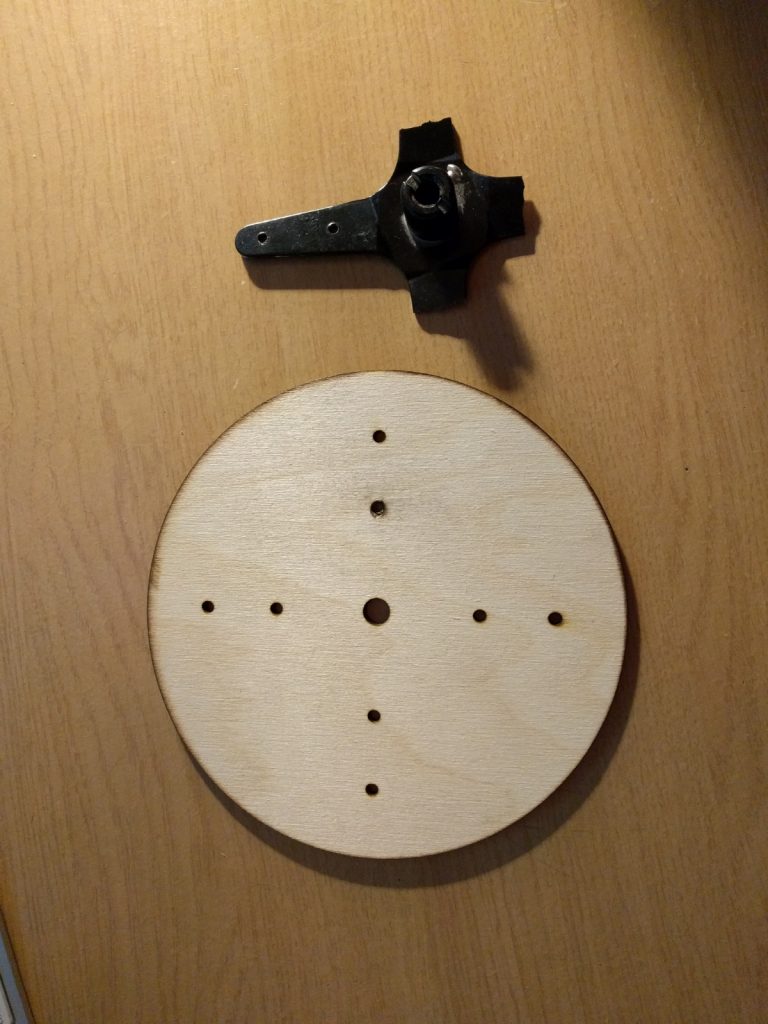

During the hot hot hot Summer our fan broke. One of the blades ripped itself free and over time another two just sort of fell off. The metal ummm thing that was holding the blades on must have just got old and tired. This is a job for my laser cutter, thought I.

I attached the blades….

and then attached the whole thing to the fan.

It was only at this moment, after several months thought and planning, did I notice that the arm of the metal thing was kind of angled…to kind of angle the blade and make it move air and stuff. The way mine is set up those blades are just going to efficiently slice through the air and make barely a draught.

Can I be bothered having another go at fixing it or does it just get recycled???

Making room for a new car

Saturday Mornings

Farewell Facebook

For a long time I’ve been an avid Facebook user. Posting several times a day. Slavishly checking for new updates every second of personal downtime. I even realised there was a gap in the Android market and wrote a Facebook Android App before Facebook got around to it. I got a cease and desist letter from FB lawyers but that’s another story.

Well, today I de-activated my account. Lost interest. Really can’t be arsed with the banality of it anymore. If I have anything exciting to share with the world then I’ll post it here…and the world won’t actually see it 🙂

I deleted my twitter account a few months ago too. So I appear to be following in the footsteps of Eric Cartman and dropping off all social media…well, it is all a bit shit really isn’t it?